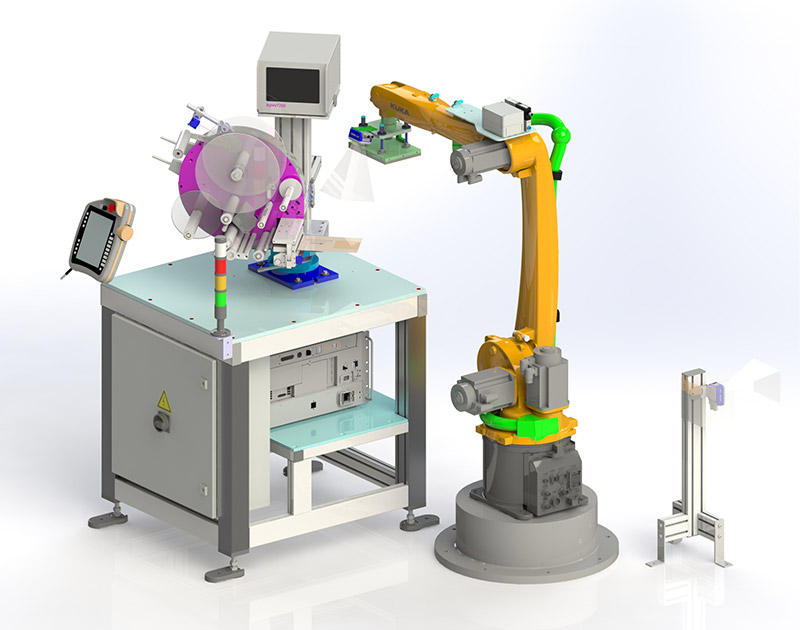

At a well known manufacturer of complete heating systems and corresponding accessories, stretch-wrapped products on shipping pallets are labelled with an A5 label. The label is applied by a 6-axis robot system.

The pallets are stopped on the customer's on-site conveyor in labelling position at the topex thermal transfer labelling machine (labelling station).

A "pallet in position" signal is then emitted by the on-site PLC. The variable print data is transferred to the topex printer. The label is then printed and pushed onto the vacuum stamp.

The vacuum stamp is built into the robot. The robot moves to the correct labelling position on the pallet and applies the label. An integrated barcode scanner verifies the printed barcode and reports the result to the higher-level line controller. This machine design allows flexible label positioning on several sides of the pallet.

After this, the robot moves back to its home position, an enable signal is emitted and the pallet is transported away from the labelling station by the customer's own system.