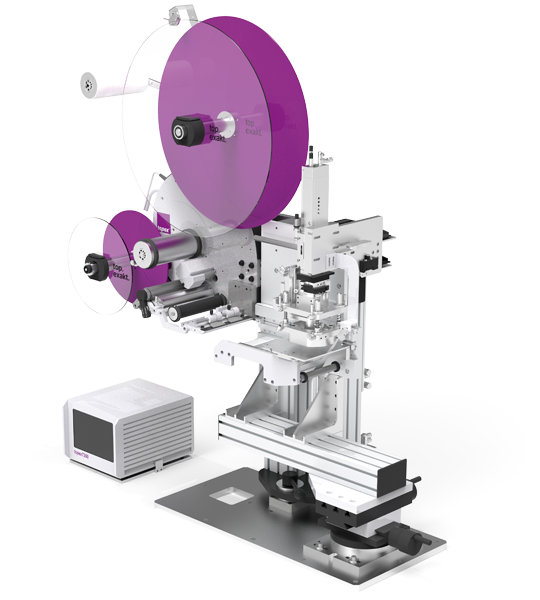

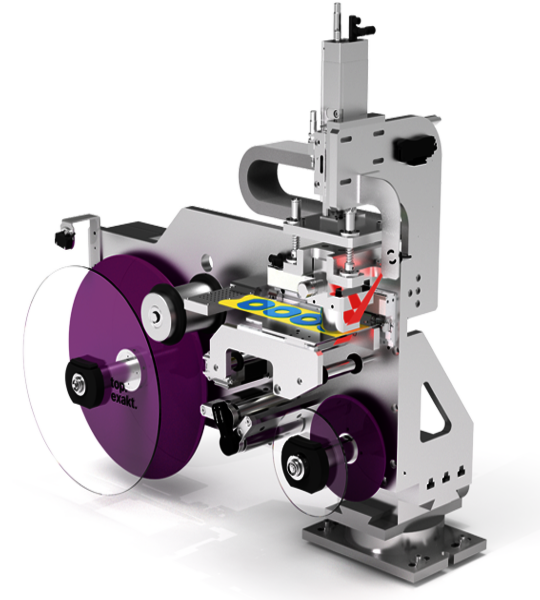

Designed for automated processing of self-adhesive functional components, our special dispensers are the right choice for your process. The topex special dispensing systems are adapted to project-specific requirements and individually tailored to roll assembly, label format, label geometry, etc. All in line with the topex motto, ŌĆ£automated labellingŌĆØ

topex modified standard dispenser with

Vacuum stamp with special contour and integral centring, available in various designs

Material: Foamed seal

Material: Foamed tubes

Quick-change vacuum stamp set with RFID function

Material: Seals, multi-line, 11 variants with different geometries possible

Thanks to a high degree of material diversity, we can process a variety of materials and offer you bespoke solutions. Whether it's integration-ready systems, semi-automatic or fully automatic solutions ŌĆō we have the right option for you.

As your system supplier, we not only provide comprehensive consulting, but also deliver appropriate consumables to support your processes.

Materials

Types of materials

Self-adhesive materials

Non-self-adhesive materials

topex offers the appropriate automation solution for every material!

Design

Material

Rolls

Other designs available on request.

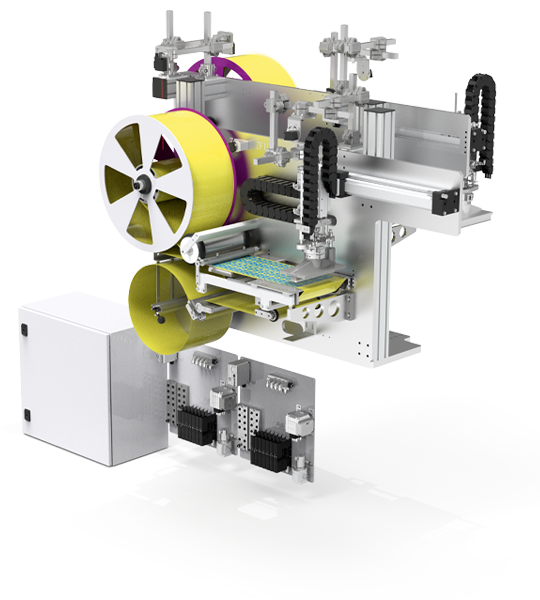

Our dispensing systems offer product and project-specific designs tailored to your individual requirements. In addition, we offer flexible control options.

Hardware

Process

Interface

Roll holder with 6-inch core

without screw connection, tool-free

Adjustable dispensing edge

pneumatically or electrically

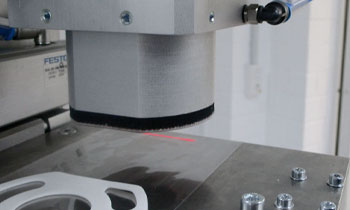

Laser cutter

for contactless cutting

Vacuum brake

e.g. for foam pads

Splicing unit

manual or fully automatic

![[Translate to English:] Anti-Haft beschichtete Bauteile [Translate to English:] Anti-Haft beschichtete Bauteile](/fileadmin/_processed_/1/b/csm_antihaft_b872689c0e.jpg)

Non-stick

components

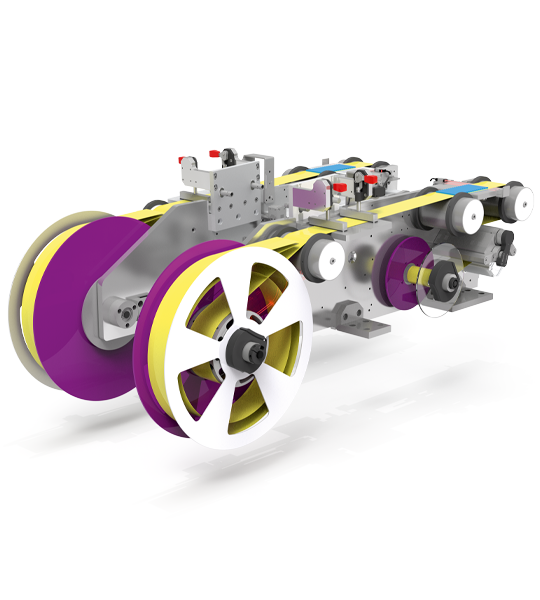

Our handling solutions and special dispensers offer innovative approaches to automating your production processes. We offer a wide range of hardware applicators using both pneumatic and electric drives to perform precise movements that require a high level of accuracy and flexibility. Various hardware grippers are available for handling objects. This ensures that your processes run efficiently and reliably.

Hardware applicators

Hardware grippers

Pneumatic drive

for precise movements

Handling robots

for flexible handling

Vacuum gripper

with spread function

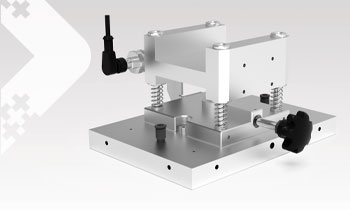

Quick-change stamp unit for quick

retooling for different label formats

Centring unit

for precise application, e.g. for PCEs

Needle grippers

for example for application of foam pads

Task

Function

The plastic housing to be labelled is transported to the labelling position on site, correctly oriented and accurately positioned. In parallel, the stamped part is automatically unwound from the large roll (diameter 400 mm) and placed on the dispensing edge of the topex special label dispenser for removal. A pneumatically operated vacuum stamp moves over the stamped part, the vacuum is activated, and the stamped part is fixed to the vacuum stamp. The backing film is now pulled away under the stamped part using a pneumatically retractable dispensing edge. The individual stamped part is automatically applied to the pre-prepared plastic housing.

Features

Benefits

Label adjustment

Pneumatically retractable dispensing edge

Fine adjustment

Label end warning