Printing and Labelling systems

Thermo-transfer labelling machines

Discover the whole range

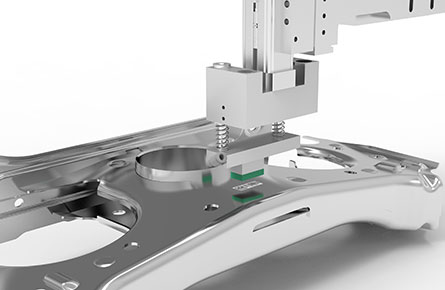

Unsurpassed versatility and compact design. The 7000 series is the right solution when great application flexibility is required and the highest demands are placed on labelling system. Whether for text, barcodes, 2D codes or graphics – top quality applies across the board. Reliable and safe – with thermal transfer printing technology.

![[Translate to English:] Druck- und Etikettiersysteme [Translate to English:] Druck- und Etikettiersysteme](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-rechts-mit-handling.jpg)

![[Translate to English:] Druck- und Etikettiersysteme [Translate to English:] Druck- und Etikettiersysteme](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-links-mit-handling.jpg)

![[Translate to English:] Druck- und Etikettiermaschinen [Translate to English:] Druck- und Etikettiermaschinen](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-rechts.jpg)

![[Translate to English:] Druck- und Etikettiermaschinen [Translate to English:] Druck- und Etikettiermaschinen](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-links.jpg)

![[Translate to English:] Etikettendruck [Translate to English:] Etikettendruck](/fileadmin/templates/_media/produkte/etikettiersysteme/etikettendruck.jpg)

![[Translate to English:] Druckbreiten [Translate to English:] Druckbreiten](/fileadmin/templates/_media/produkte/etikettiersysteme/druckbreiten.jpg)

![[Translate to English:] Etikettierendevorwarnung [Translate to English:] Etikettierendevorwarnung](/fileadmin/templates/_media/produkte/etikettiersysteme/etikettierende-vorwarnung.jpg)

![[Translate to English:] Etiketten Zentriereinheit [Translate to English:] Etiketten Zentriereinheit](/fileadmin/templates/_media/produkte/etikettiersysteme/greiferbacken-geschlossen.jpg)

![[Translate to English:] Wechselstempel [Translate to English:] Wechselstempel](/fileadmin/templates/_media/produkte/etikettiersysteme/wechselstempel.jpg)

![[Translate to English:] Führungsringe [Translate to English:] Führungsringe](/fileadmin/templates/_media/produkte/facelift/Fuehrungsringe.jpg)

![[Translate to English:] Druckkopf-Cleaner [Translate to English:] Druckkopf-Cleaner](/fileadmin/templates/_media/produkte/facelift/Druckkopf_Cleaner.jpg)

![[Translate to English:] Hilfslust Drossel [Translate to English:] Hilfslust Drossel](/fileadmin/templates/_media/produkte/facelift/Druckkopf_Hilfsluft-Drossel.jpg)

![[Translate to English:] Mechanische Vorteile Drucken und Etikettieren [Translate to English:] Mechanische Vorteile Drucken und Etikettieren](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-mechanisch01.jpg)

![[Translate to English:] Mechanische Vorteile Drucken und Etikettieren [Translate to English:] Mechanische Vorteile Drucken und Etikettieren](/fileadmin/templates/_media/produkte/etikettiersysteme/druck-und-etikettiersystem-mechanisch02.jpg)

![[Translate to English:] Steuerung von Etikettiersystemen [Translate to English:] Steuerung von Etikettiersystemen](/fileadmin/templates/_media/produkte/etikettiersysteme/steuerung-etikettiersysteme.jpg)