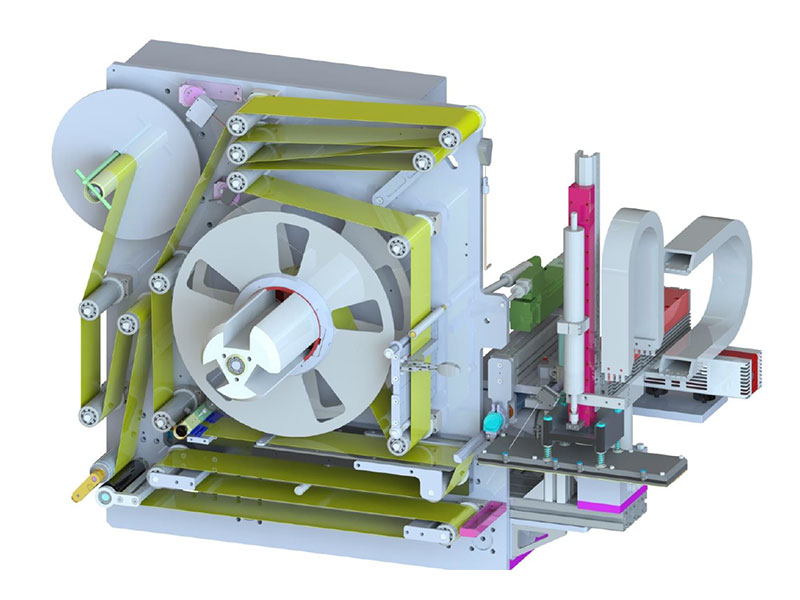

The topex labelling unit is characterised by a high degree of flexibility. Since the actual battery cells are produced in different formats, the formats of the corresponding foils also change.

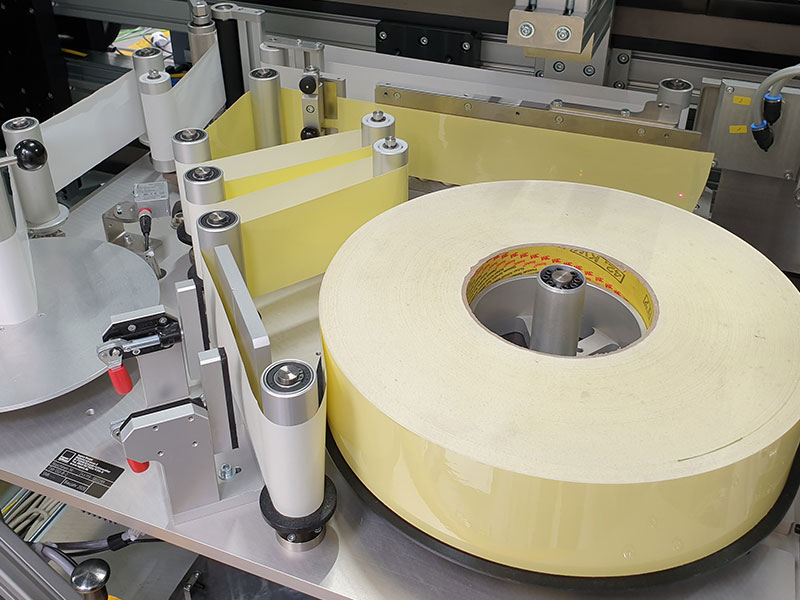

The solution is an endless roll of foil, which is cut to the appropriate size inline as part of the process.

A special CO2 laser with a corresponding cutting head is used for this purpose.

The separated foil sections are then transferred to the battery body via a two-axis pick-and-place linear handling system with an integrated vacuum suction plate.

This technology achieves the required cycle time of approx. 3 seconds.

Customer benefits

- Flexible use of the system for different battery types

- No contamination due to contactless laser cutting

- No need to change the rolls due to the use of endless foil

Features

- Motorised label roll unwinding

- Motorised backing paper winding

- Foil transport – servomotor-operated

- Motor-retractable dispensing edge for variable production

- Servomotor-operated pick-and-place handling system

- 20 W CO2 cutting laser with cutting head

- Manual splicing table

- Siemens S71500 controller