At a well known German pharmaceutical company, the task was to integrate a flexible, fully automatic pallet labelling unit into the end-of-line area.

The pallets are automatically fed by the conveyor system and stopped at the labelling position. A5 labels are applied to the side and front of the pallet.

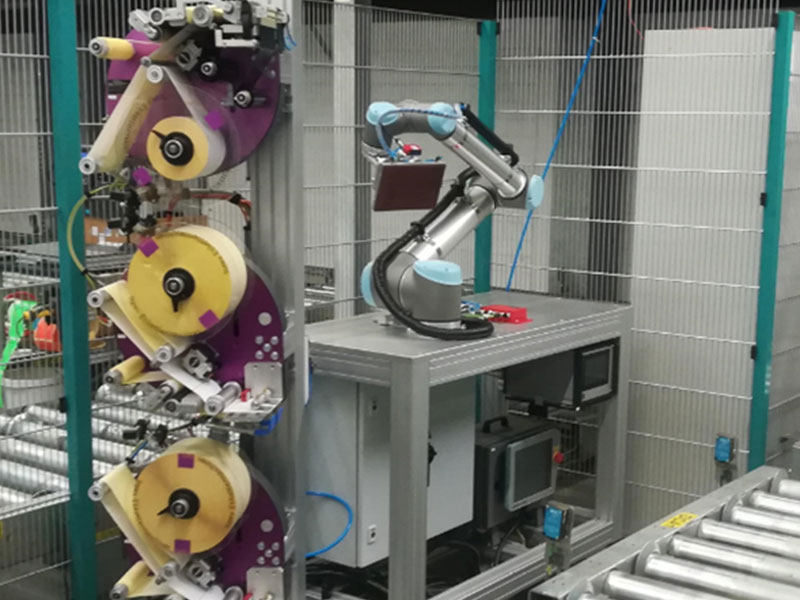

Since two pre-printed labels measuring 105 mm x 144 mm are processed in addition to the variably printed EAN shipping label, a flexible, robot-supported design was chosen. The robot can reach all three labellers and all relevant labelling positions on the pallet.

Features of the topex pallet labelling system

- topex 7162-12-300 thermal transfer printer

- 2 topex 7162-00-300 label dispensers

- 5-axis lightweight robot with vacuum tooling

- Integrated barcode scanner

- Aluminium profile superstructure

- Siemens S7-1500 PLC with Comfort Panel

- Data connection to the higher-level line controller